Sustainable Concrete Performance

MasterCO2re for low - clinker concrete production

Simplifying Complexity

Concrete production accounts for about 8% of man-made CO2 emissions worldwide, of which up to 90% is due to cement clinker production. Substituting clinker contained in cement and ultimately in concrete with alternative materials such as limestone filler or supplementary cementitious materials (SCMs) can save considerable amounts of carbon emissions. However, these more sustainable materials do not come without their own challenges and influence the concrete properties: Loss in workability, worsening of rheology, and the reduction of strength.

The intelligent cluster system MasterCO2re overcomes performance gaps associated with low-clinker concrete production supporting our customer's demanding process to reduce clinker and achieve sustainable concrete performance.

Superb Workability Retention

Thanks to the intelligent cluster system, MasterCO2re releases the polymer over time, ensuring consistent flowability and workability during concrete transport and placement.

Advanced Rheology

Concrete with the advanced MasterCO2re technology has a lower viscosity than conventional superplasticizers. As a result, concrete is easier and faster to pump and place. The water content can be further reduced without affecting the rheological properties, even in concrete mixes with reduced clinker content.

Excellent Strength Properties

MasterCO2re promotes the formation of a dense and homogeneous structure of cement hydrates, resulting in optimal strength development.

Unmatched Robustness

With rapidly changing cement types and binder compositions, the stability and quality consistency is a challenge in the daily operation of concrete plants. MasterCO2re successfully counteracts the potential of high-water absorption and undesirable interactions with admixtures caused by variations in the chemical and mineralogical composition of binders.

Three Ways to Reduce Clinker

Cement type

Through the usage of cements with lower clinker content

Cement dosage

By reducing the cement amount in concrete

Blending

Replacing part of the cement with supplementary cementitious materials (SCMs)

MasterCO2re pushes the limits of low-clinker concrete by enabling the easy usage of high volumes of clinker substitutes while safeguarding substantial performance characteristics.

Intelligent Cluster System

MasterCO2re is a game-changing technology based on an intelligent cluster system (ICS) that delivers its effects precisely when required. A portion of its freely available polymers is immediately dispersed for initial water reduction. The finely tuned chemical structures of the diverse clusters optimise both workability retention and cement hydration by adapting the polymers' release mechanism to the cement matrix's characteristics.

MasterCO2re reliably ensures excellent flowability and rheology even at high temperatures, allowing easy pumping and placing of concrete.

Decide NOW for low-clinker concrete recipes

Downloads

Download more helpful information and gain valuable insight into the performance results achieved with MasterCO2re related to ready-mix and precast applications. In addition, discover the CO2, water, and cost savings that MasterCO2re can unlock.

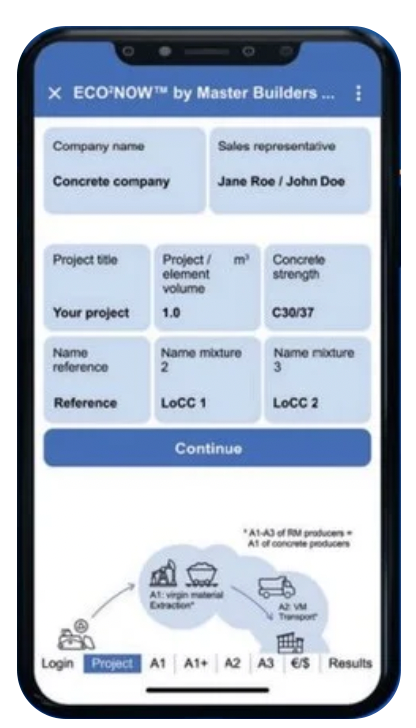

With the help of the ECO2NOW App, we will also support you in the decision-making on how to lower CO2 in your concrete recipe.

ECO2NOW™ Concrete Calculator

Rising energy and raw material prices and the need to switch to more sustainable production methods are currently the biggest challenges for the construction industry. The increasing cost pressure makes sustainable action more difficult. However, sustainability and economic efficiency are not mutually exclusive and go hand in hand.

Do you also want to make a sustainable contribution and optimize your concrete mix in terms of CO2 and costs? Don't loose time and set up a meeting with your local Master Builders Solutions expert today.

Learn more about our work

MasterCO2re Intelligent Cluster System: Watch our video for insights into the unique mechanism of action.

MasterCO2re: Watch Promsa – Cementos Molins’ success story

MasterCO2re: Watch KP1's, prefabrication specialist, success story

Laboratory tests for ready-mix at Master Builders Solutions' R&D centre in Treviso, Italy

Laboratory tests for precast at Master Builders Solutions' R&D centre in Treviso, Italy

Any questions?