Street Address

RUA NOSSA SRA. DA CONCEIÇÃO 4,

2630-506 LISBOA

Advanced technologies and sustainable practices for durable concrete floors

It is estimated that around 15% of concrete worldwide is used for the production of industrial floors, a critical component in various sectors, from warehouses and factories to commercial spaces and public infrastructure. The quality and durability of these floors are paramount, as they must withstand heavy traffic, mechanical loads, and environmental stresses. Master Builders Solutions is at the forefront of providing innovative solutions that enhance the performance and longevity of industrial floors, ensuring they meet the highest standards of strength, durability, and sustainability.

Common challenges in industrial flooring

Withstanding Loads

Industrial concrete floors must endure significant stresses from heavy machinery, equipment, and constant foot traffic. Ensuring that the flooring can withstand these heavy loads without deteriorating is a critical challenge. The continuous movement of forklifts and other heavy equipment can cause substantial wear on the surface, leading to cracks and a decrease in structural integrity over time. Addressing this issue requires a focus on enhancing the concrete’s load-bearing capacity and durability to ensure long-lasting performance.

Time-Effective Production/Installation

In industrial settings, the speed and efficiency of producing and installing concrete flooring are crucial. Projects often operate under tight deadlines, and delays can have significant financial implications. Coordinating the various stages of production and installation, including mixing, pouring, finishing, and curing, is complex and time-consuming. Environmental conditions, such as temperature and humidity, can further complicate the process. Efficient production and installation processes are essential to minimize downtime and ensure that facilities can return to full functionality swiftly.

Shrinkage

Shrinkage is a common issue that can severely impact the integrity and durability of concrete flooring. This occurs as the concrete loses moisture and undergoes chemical changes, leading to a reduction in volume. Shrinkage can cause cracking, warping, and other structural issues, compromising the longevity of the flooring. There are various types of shrinkage, including plastic shrinkage, drying shrinkage, and autogenous shrinkage, each presenting unique challenges. Managing shrinkage effectively requires careful planning, proper mix design, and the use of appropriate additives.

Freeze-thaw cycles

In regions with harsh climates, freeze-thaw cycles present a significant challenge for external pavements. When temperatures drop below freezing, the water within the concrete expands as it turns to ice, exerting pressure that can damage the concrete matrix. The cyclical process of freezing and thawing causes the concrete surface to deteriorate over time, leading to crumbling and delamination. Industrial floors exposed to outdoor environments are particularly vulnerable to this issue. Improving the concrete’s resistance to freeze-thaw cycles is essential to prevent damage and ensure long-term durability.

Comfort of Use

In industrial settings, the comfort of use of concrete flooring is crucial for both operational efficiency and worker well-being. Smooth and stable floors support efficient movement of machinery and personnel, while uneven or damaged flooring can cause discomfort, increase accident risk, and reduce productivity. Joints in the flooring can create a jarring "clicking" sensation for machinery operators, leading to discomfort and equipment wear. A floor with fewer joints minimizes these issues, providing a smoother ride and reducing maintenance costs. Enhanced comfort and fewer disruptions lead to greater efficiency and productivity, allowing workers to maneuver machinery more swiftly and precisely.

Durability

Durability is essential for industrial concrete flooring, which must withstand various stresses without compromising structural integrity. Heavy machinery and equipment cause significant surface wear, while exposure to chemicals and oils can lead to deterioration. Temperature fluctuations can cause the concrete to expand and contract, resulting in cracks. Abrasion from machinery and foot traffic further reduces the floor's lifespan. Ensuring durability involves selecting the right materials, using appropriate construction techniques, and implementing regular maintenance. Durable flooring resists wear and tear, withstands heavy loads, and maintains structural integrity over time, reducing the need for frequent repairs and extending the floor's service life.

Products for industrial concrete floors

Superplasticizers

Our specific product lines MasterGlenium, MasterEase, MasterCO2re are designed to reduce the water/cement ratio, ensuring fluidity, and maintaining mechanical properties.

Shrinkage Compensating Agents

Our comprehensive range MasterLife includes a series paramount products for addressing shrinkage in concrete, which can cause cracking and structural issues.

Accelerators

Accelerators like Master X-Seed and MasterSet AC are specialized admixtures designed to enhance the early strength development of concrete.

Fibers

The use of fibers in concrete technology enhances the performance and durability of industrial flooring by mitigating common issues such as shrinkage and cracking. In particular, our MasterFiber range includes solutions that use macro-fibers or micro-fibers offering distinct benefits.

Curing agents

Our comprehensive range of curing agents MasterKure is designed to ensure the optimal hydration of concrete, thereby enhancing its strength, durability, and overall performance in industrial flooring.

Air-entraining admixtures and mineral additives

Our ranges MasterAir, MasterSphere and MasterLife MS enhance the concrete's performance by improving its durability, workability, and resistance to environmental stresses.

Master Builders Solutions offers a comprehensive range of products designed to address the unique challenges of industrial flooring.

Tool4Floors

SRA Calculator

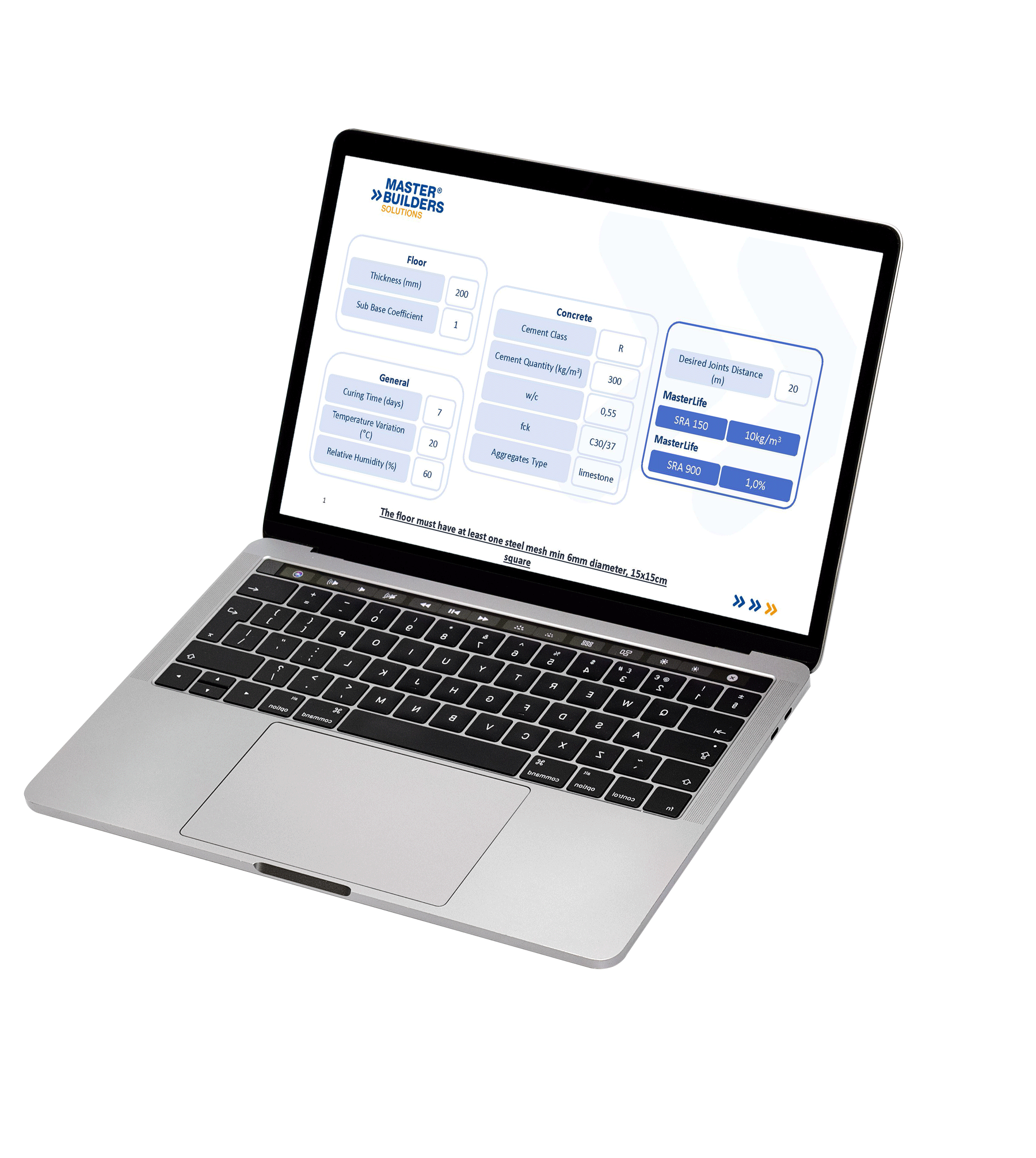

Introducing the MasterLife SRA Dosage Tool from Master Builders Solutions, a revolutionary solution for the estimation of the optimal dosage of shrinkage compensating agents for concrete floors.

For the first time in the industry, we offer a tool that provides tailored dosage recommendations based on the specific parameters and data input by the project designer.

By entering exact project details, such as concrete mix design, floor dimensions, joint spacing, and environmental conditions, Tool4Floors calculates the optimal amount of additives needed, ensuring the best flooring solution.

Benefits of Tool4Floors:

- Optimized performance

- Enhanced structural integrity

- Increased comfort and safety

- Cost efficiency

With Tool4Floors, Master Builders Solutions sets a new standard in the industry, offering a reliable and efficient way to enhance the quality and longevity of concrete flooring.

Interested in our Tool?

Contact me now!