Technology for SLS by Master Builders Solutions is a unique admixture package for cementitious self-levelling screeds (SLS) that supersedes conventional techniques: it is less time consuming, reduces construction costs and allows easy processing and quick installation of screed in a reliable and more sustainable way.

At the core of this economic and sustainable technology is the innovative compound MasterLife SLS, which overcomes common problems with shrinkage and curling.

The new self-levelling screed technology can be directly supplied by the ready-mix concrete provider or by the screed applicator. This eliminates the need for silos of self-levelling compounds at the job-site.

Our time-saving admixture package for cementitious self-levelling screed (SLS) provides an outstanding flowability and prolonged workability, resulting in an improved surface quality. The self-levelling screed produced with our products is up to ten times faster as it takes 2-3 workers to lay only 200 m² of dry screed per day, while with our new technology the same team can place and finish up to 1,000 m² of self-levelling screed in the same time. It requires less placing labor, no special labor skills and consequently saves time and costs - applying screed has never been so easy!

Are you ready...

…for an application with a much higher throughput?

…for a much less stressful work?

…for a concrete for your screed that has a superior rheology, better pumpability and is stable against segregation?

…for a screed that doesn’t need any secondary treatment nor polishing?

…for concrete that keeps the fluidity as long as you need to complete your job?

…for a screed with a fantastic surface that is homogeneous and without defects?

…for a screed that can be produced in a fast and reliable way in every season?

…for Technology for SLS?

We all know what it’s like - waiting for screed to dry is time consuming and time is money! Speeding up the construction process requires innovative solutions that significantly improve the rheology of screed to allow an easier processing and faster installation. The Technology for SLS is also an outstanding and economic alternative to the self-levelling compounds in silos. With our innovative package of admixtures, the production and delivery of cementitious self-levelling screeds is easy, reliable and fast.

Fast drying times, rapid entry for the finishing work, fulfillment of norms and a fast construction progress to cope with tight time schedules: Yesterday impossible, today a reality!

Are you ready…

…for a more economic solution?

…for a solution to reduce your construction time?

…for an easy installation on your construction site?

…for a superior surface finish?

…for a solution that allows you to skip further treatment or levelling toppings?

…for an energy-saving solution thanks to the superior conductivity of the screed, in case of floor heating systems?

…for a screed with a significant positive impact on sustainability?

…for Technology for SLS?

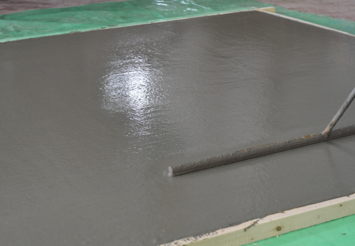

With our innovative technology for cementitious self-levelling screed (SLS), you can reliably produce and deliver concrete screed without any concerns. The fresh concrete is stable and has an optimal rheology, which in turn facilitates pumping and finishing. The fluidity is maintained throughout the time required to complete the job. The hardened concrete meets the mechanical requirements, has no cracks on the surface, significantly reduces shrinkage and curling and looks smooth and homogeneous in the final result ─ just perfect!

Are you ready…

…for a new positioning in the market?

…for a new chance to extend your portfolio?

…for a solution that offers differentiation potential?

…for a screed solution that fulfills EU technology norms?

…for an innovative screed technology that offers easy processing?

…for Technology for SLS?

The breakthrough innovation Technology for SLS has been selected by the ready-mix producer RAK-BUD for the construction of a complex of modern multi-floor apartments in Bialystok, Poland, as it enables cost reduction, optimal rheology and extended workability.

Why choose Technology for SLS? Discover the whole success story!

Laying and finishing 3x3m slabs took less than half the time with Master Builders Solutions' SLS compared to dry screed. This results in significant time, labor and money savings and is especially important when schedules are tight on construction sites. The well-being and comfort of the workers is another important factor in favor of the innovative SLS technology: the production of self-leveling screed is not only faster, but also far easier and less tiring for the workers.

*The tests were carried out with the support of the accredited lab SOCOTEC.

We not only offer you a technology that facilitates your on-site workflows, but also the expertise and technical support of our

Master Builders Solutions experts to bring construction to a new level.

© Master Builders Solutions

Data privacy | Disclaimer | Credits |